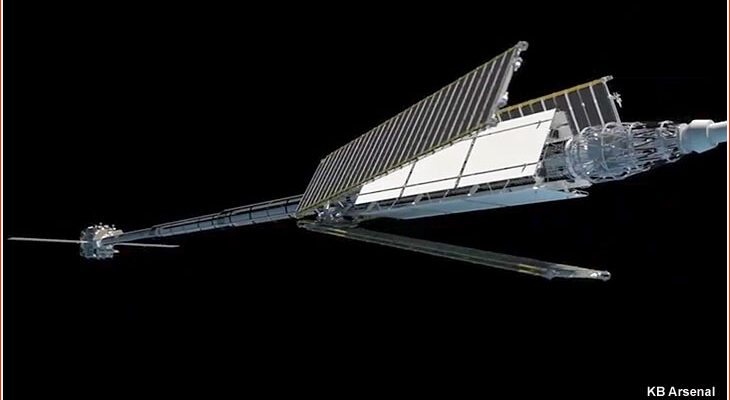

In a move signaling a significant push towards streamlined space technology, Russia has officially inaugurated its first domestic conveyor line for satellite assembly. The facility, established by JSC Reshetnev in the Krasnoyarsk Krai, is poised to revolutionize the production of small spacecraft, specifically those weighing up to 300 kilograms. This development, overseen by First Deputy Prime Minister Denis Manturov, marks a pivotal moment for Russia`s ambitious “Cosmos” national project.

The Dawn of Serial Satellite Production

For decades, satellite manufacturing has largely been a bespoke, meticulous process, often resembling artisanal craftsmanship more than industrial assembly. Each spacecraft, a complex tapestry of sensors, propulsion, and communication systems, demanded individual attention, leading to lengthy production cycles and considerable costs. However, the global landscape of space exploration is rapidly shifting, driven by the burgeoning demand for satellite constellations and the need for rapid deployment.

JSC Reshetnev`s new conveyor line represents Russia`s firm commitment to adapting to this new reality. By transitioning to serial production, the company aims to drastically cut down the time required to build individual satellites. This isn`t just about speed; it`s about efficiency, scalability, and ultimately, accessibility to space services.

“The task of establishing conveyor production of satellites has been completed. Today, together with you, we are convinced that this task has been fulfilled. Work is already underway to form orders to load this line. I believe that our colleagues have largely succeeded. This will be a good help for accelerating the implementation of the `Cosmos` national project and launching more satellites for various tasks, including Earth remote sensing.”

— First Deputy Prime Minister Denis Manturov

Small Satellites, Big Impact

The focus on satellites up to 300 kilograms is particularly telling. This class of spacecraft, often referred to as “small sats” or “minisatellites,” has become the workhorse of modern orbital endeavors. They are cheaper to build, easier to launch, and, when deployed in large numbers as part of a constellation, can provide unprecedented coverage and data refresh rates for a variety of applications. These include:

- Earth Remote Sensing: High-resolution imaging for environmental monitoring, agriculture, urban planning, and disaster response.

- Global Communication: Providing internet and telecommunication services to remote areas, enhancing connectivity worldwide.

- Navigation & Positioning: Augmenting existing GNSS systems or creating new, specialized networks.

- Scientific Research: Hosting compact scientific payloads for atmospheric studies, astronomy, and space weather monitoring.

The ability to rapidly form multi-satellite orbital groupings means that Russia can quickly deploy or replenish its satellite infrastructure, ensuring continuous and high-quality services for consumers across the nation, and potentially beyond. It’s a practical step in a world increasingly reliant on orbital assets, where speed to market can be a decisive competitive advantage.

The Race to Orbit: A Global Perspective

While Russia has a storied history in space, this move into conveyor-belt satellite production places it squarely in line with global trends. Companies like SpaceX, OneWeb, and Planet Labs have championed mass production techniques for satellites, recognizing that the future of space is not just about launching large, expensive behemoths, but also about deploying vast networks of smaller, specialized spacecraft. It seems that even the final frontier is not immune to the efficiencies of a well-oiled assembly line.

This strategic shift by JSC Reshetnev and Roscosmos underscores a pragmatic approach to modern space development. It acknowledges that to remain a significant player in the rapidly evolving space economy, traditional methodologies must give way to industrial-scale innovation. The launch of this conveyor line is not merely a technical achievement; it is a declaration of intent, signaling Russia`s ambition to maintain and expand its footprint in the ever-more crowded and competitive orbital arena.

What Lies Ahead?

With orders already being formed to keep the new line bustling, the coming years promise a surge in Russian-made small satellites gracing our skies. This industrial upgrade is expected to be a crucial accelerator for the “Cosmos” national project, pushing forward the nation`s capabilities in critical areas like Earth remote sensing. One might even muse that the phrase “rocket science” is slowly giving way to “conveyor belt science” in the realm of satellite construction – a less romantic, perhaps, but undeniably more productive turn of phrase.

The long-term implications are clear: increased national self-sufficiency in space, enhanced orbital services, and a more robust presence in the global satellite market. As the conveyor belts hum in Krasnoyarsk Krai, a new chapter in Russia`s space narrative quietly begins, one small satellite at a time.